CLOSE TOLERANCE AUTOMOTIVE PARTS

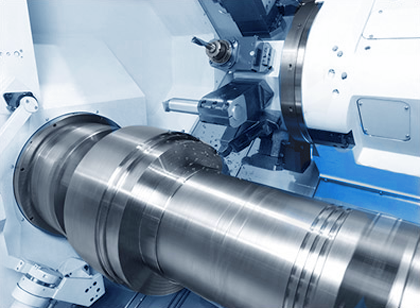

We combine the latest Computer Numerically Controlled (CNC) machining and turning processes with proprietary state-of-the-art technologies to deliver the highest quality automotive parts – at the most competitive price points, with the shortest lead times.

Our multiple CNC turning centers and lathes are staffed by highly trained and experienced machinists, engineers and turning specialists – using subtractive machining combined with proprietary automation software – to deliver the most accurate and durable parts in record time.

Our turning process also includes live tooling to create off-axis holes, flats, slots and grooves – from the widest selection of engineering-grade materials available, including: aluminum, brass, copper, stainless steel, polycarbonate, iron, and more.

And while our machines have automatic test features, our Quality Team still implements manual checks at every stage to ensure that the highest & most consistent level of quality is always maintained.

CUSTOMER BASE

Top 4 (99% of Business)

Ford Motor Company

Neapco Drive Lines

DANA

All Others

AER Manufacturing • Hollingsworth

Borg Warner • Magna • General Motors

ATC Drivetrain • Dayco Products

CNC MACHINED PRODUCTS

Powertrain Components

Transmission Flanges

Axle Flanges

Slip Yokes

QUALITY CERTIFICATIONS

IATF16949:2016 • CQI-9 Certified

ISO 14001 • Q1 Status